Buy your weekday smoothies and get your weekend ones for free. (7 for the price of 5!)

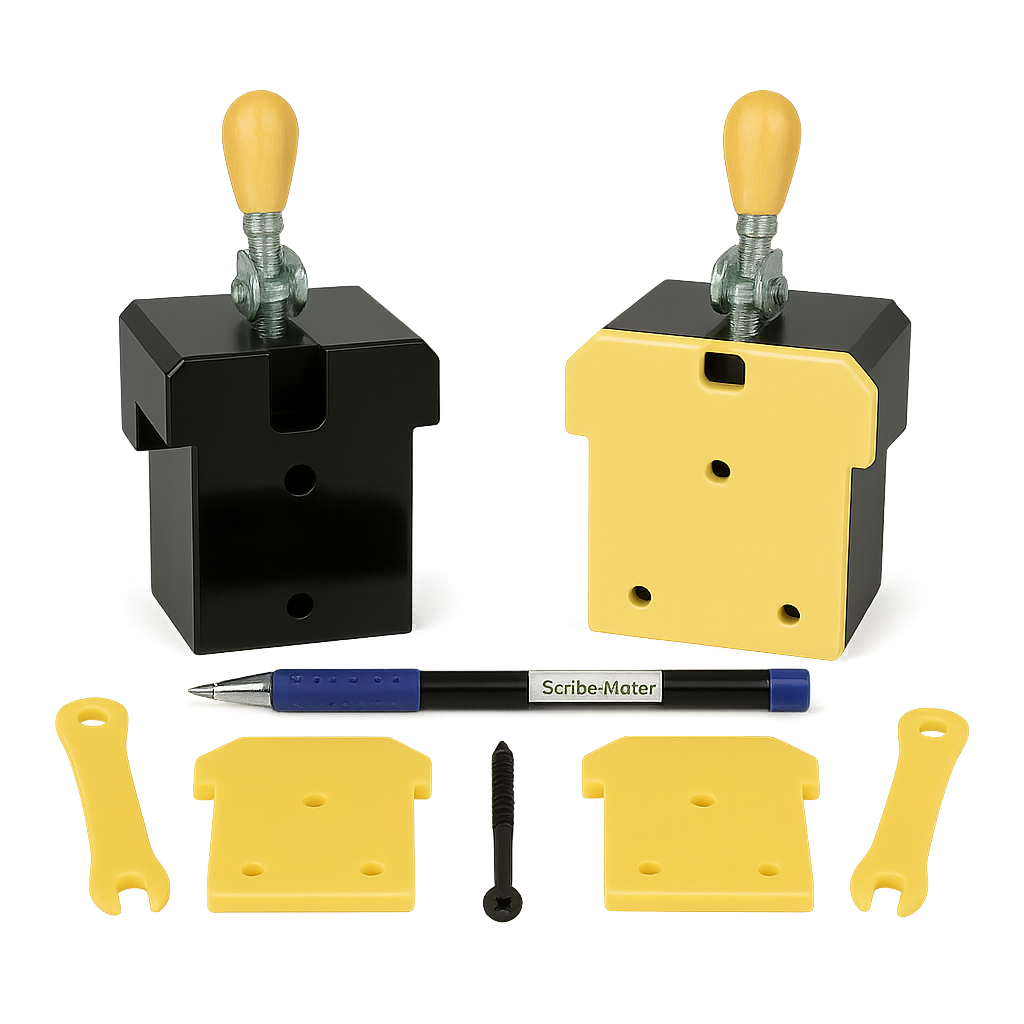

Scribing a cabinet panel so it sits flush against uneven walls or surfaces is one of those jobs that separates a tidy finish from a frustrating one. Traditionally, it can be fiddly, time-consuming, and easy to get wrong. But with the Scribe-Mate tool and a few clear techniques, achieving a professional scribe line on the first cut becomes a straightforward process.

Below, we’ll walk through the main methods and situations you’ll encounter—whether you’re dealing with pre-drilled hinge holes, corner placements, long plinths, or stepped cabinet panels.

1. Scribing Using Pre-Drilled Hinge Holes

Most cabinets arrive with standard hinge plate holes—commonly 5 mm or 3 mm in diameter. Scribe-Mate is designed to work seamlessly with both:

-

Insert the location pins into the correct holes (directly for 5 mm; with shims for 3 mm).

-

Fix the jig gently using the supplied bugle-head screws—firm enough to hold, but without overtightening.

-

Position your fillet so it sits snugly against the jig’s clean edge and secure with a clamp.

-

Glide the scribing tool smoothly along the surface and cut precisely to the marked line.

The result is a fillet that fits tightly with minimal need for caulking—a clean, professional outcome every time.

2. What to Do When There Are No Pre-Drilled Holes

Not every cabinet is supplied with hinge holes, but there are two reliable workarounds:

Option A – Using the Cabinet Corner

-

Place a “shoulder” of the jig into the cabinet’s corner.

-

Secure it, clamp the fillet as usual, and scribe along the edge.

Option B – Using a Location Plate

-

Fix a location plate opposite the jig’s pins.

-

Secure the jig block in place, clamp the fillet, and mark your line.

-

Remember to remove the plate before attaching the fillet—otherwise, you’ll scribe 3 mm too narrow.

3. Handling Plinths and Top Fillets

For plinths and top panels where corners are your reference points:

-

Insert the jig shoulder into the inside corner (top or bottom).

-

Place a second jig in the opposite corner and clamp your fillet.

-

For longer runs, introduce a third jig with a location plate to maintain stability.

This setup keeps your scribe line consistent across extended lengths, avoiding drift or misalignment.

4. Overcoming Cabinet Panel Steps

Uneven panel depths are a common challenge, especially when cabinets sit slightly out of line. To handle this:

-

Measure the thickness of the step.

-

Insert equal shims between the jig and the panel on both sides.

-

Mark and cut your line as normal.

This ensures the fillet remains uniform, preventing the uneven cuts that can result from stepped cabinet faces.

5. Important Finishing Notes

-

The screw holes used to secure the jig double as fixing points for the fillets themselves.

-

In most cases, these screws will be hidden neatly under cabinet hinges.

-

Where they remain visible, simply fit the supplied screw caps for a polished, seamless look.

The Professional Finish—Made Simple

By combining Scribe-Mate’s clever design with the right method for the job at hand, you can cut down on wasted time, reduce errors, and deliver a flawless scribe line every time. Whether you’re fitting kitchens, wardrobes, or custom cabinetry, these techniques give you precision and consistency without the usual frustration.